- Order number: KFU2-40 912

- Notice: Please inquire the desired version.

- Graduation: 1

- Minimum Quantity: 1

- Maximum Quantity: 500

Motor: 12 V, DC

Flow rate: 140 cm³/min

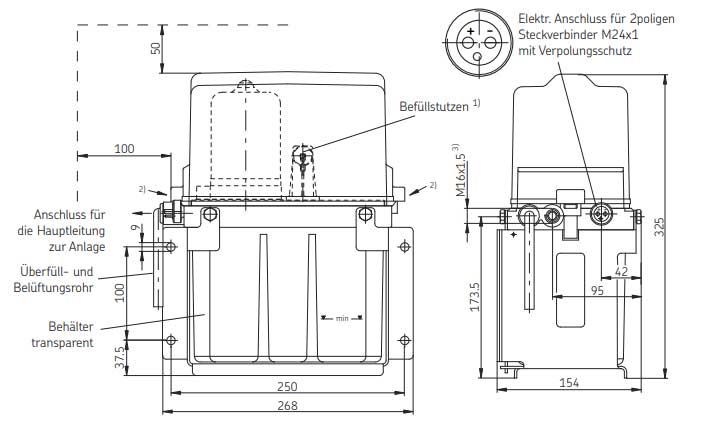

Container: 2.7 L plastic

NLGI class: 000 / 00

Flow media: fluid grease

Operating temperature: -25 to +75 °C

Operating pressure: max. 38 bar

Control unit: without

Protection class: IP 59 k

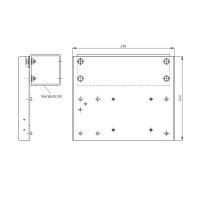

The gear pump unit essentially consists of a gear pump with relief valve, pressure relief valve, DC motor, transparent lubricant container, filling nozzle and mounting bracket. To protect against contamination, the DC motor and the filling nozzle are covered with a hood. The hood snaps into place on both sides of the container lid.

Function

The gear pump continuously pumps the lubricant through the main line to the relubrication distributors while the pump is running. As soon as the metering chambers of the distributors are full, the excess lubricant flows back into the container via the pressure relief valve.

After the pump running time has elapsed (start of the pause time), the relief valve opens so that the pressure in the main line can be reduced to a residual pressure of 0.2 to 1.0 bar. The spring-loaded pistons of the distributors can now pump the lubricant from the metering chambers to the lubrication points.

With the KFU2-40 or KFU6-20 pump unit, almost any system size in commercial vehicles, including superstructures, can be supplied by a single pump. The semitrailer or trailer can also be connected as a combined system, although this is only recommended if the motor vehicle and semitrailer are rarely or never separated.

In vehicles approved for the transport of dangerous goods on the road (GGVS), the KFU units must be used with the cable set 997-000-374.

Associated cable set for KFU, order no. 997-000-373; cable set for KFUS2-64, order no. 997-000-750.