- Order number: PAB0501CAA170E-50

- Notice: Bitte fragen Sie Ihren Preis bei uns an.

- Graduation: 1

- Minimum Quantity: 1

- Maximum Quantity: 500

| Technical Specifications

| Mechanische Ausführung

|

The pumps in the PAB group are supplied in two components, a pump component and a motor component. The type codes for the pump component and motor component therefore need to be configured separately.

| Design features:

| Variants:

|

Main areas of use

- Printing machines

- Packaging machines

- Surface coating

- Washing/degreasing installations

- Impregnation

- Electroplating baths

Their uniform, pulsation-free delivery of fluid makes Spandau centrifugal pumps especially well suited to pumping ink. Their open impeller design allows for small particles in the return flow. Adjustable drive power also makes them suitable for high viscosities.

Special design features of the PAB group

The pump section – consisting of the pump housing and flange-type end shield – is connected to the drive only by quick-release locks. This allows the drive to be removed from the pump component without having to disconnect the electrical leads. Cleaning is simpler and faster as a result. All hydraulic parts of the PAB group are compatible with most cleaning methods.

Installation and operation

The unit is installed upright. The maximum level for fluid is 20 mm below the mounting flange. Before startup, fill the pump with fluid for pumping.

Explosion-proofing

Directive 2014/34 / EU (ATEX) applies to equipment and protective systems for intended use in potentially explosive atmospheres areas.

The ATEX (ATmosphère EXplosible – potentially explosive atmosphere) applies to all “equipment” (e.g. machines, apparatus, ...) which, “separately or jointly, are intended for the generation, transfer, storage, measurement, control and conversion of energy for the processing of material and which are capable of causing an explosion through their own potential sources of ignition.”

The pump group PAB is ATEX approved – it is certified and marked accordingly. The corresponding certificates of conformity as well as type approval certificates and/or certificates of deposit are available can be obtained on request

Technical explanation of electrical versions of drive motors

“Explosion-proof enclosure” protection, EExd

The performance ratings of our pump motors refer to the motor version for explosion group IIC. The stated performance ratings and operating values are valid for ignition class T4. These ratings and values encompass all lower explosion groups and temperature classes. The motors have the following coding according to EN 60079-1: II 2G EX de IIC T4 Gb The pumps have the following coding according to EN 60079-1: PAB II 2 G c IIB T4 The stated performance ratings and operating values are valid for mode S1, the rated frequency and voltage, a maximum coolant temperature (ambient temperature) of 40 °C, and a site altitude of up to 1000 m above sea level. The motors of the pumps normally come with a 6pole terminal board for 230/400 V, delta/star. Upon delivery we switch the motors to the higher star-connected voltage of 400 V. The voltage tolerance permissible in operation is ± 5% at the rated power and frequency, in compliance with EN 60034.

Hazardous areas

The user has sole responsibility for deciding which explosion group is to be applied. In case of doubt, the relevant supervisory body may decide which protective measures are required to prevent harm. DIN 57165 and VDE 0165 classify hazardous areas into zones.

| Zone | Motor with protection class Exd - "explosion-proof enclosure" |

|---|---|

| 0 | not permitted |

| 1 | permitted |

| 2 | permitted |

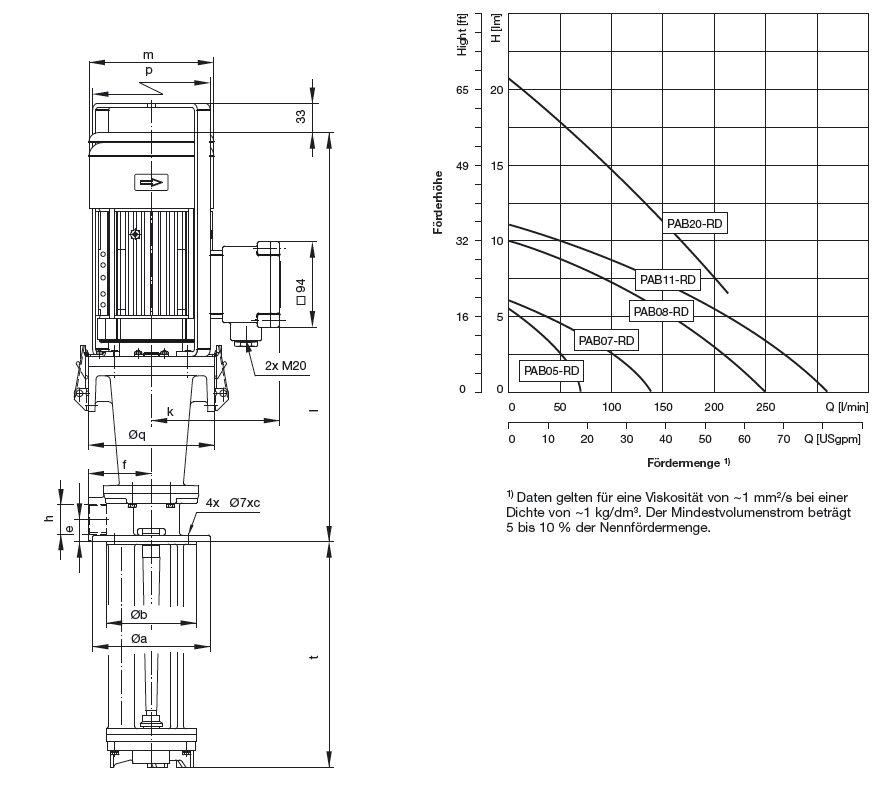

PAB - Dimensional drawing and characteristics