Previous

Next

Beispielhafte Darstellung, Produkt kann abweichen.

- Order number: LMP

- Notice: Please contact us to configure the pump suitable for your application.

- Graduation: 1

- Minimum Quantity: 1

- Maximum Quantity: 500

Media: Fluids with lubricating properties For pure fluids without abrasive or long fibre...more

Screw Pump LMP

- Media:

Fluids with lubricating properties

For pure fluids without abrasive or long fibre components - Viscosity: max. 20 mm²/s

- Kinematic viscosity: 1 to 2500 mm²/s

- Temperature range: 0°C to +80°C

- Delivery pressure: max. 120 bar

- Delivery rate: max. 670 l/min

- Electrical parameters:

≤ 4 kW: 230/400 V, 50 Hz and 265/460 V, 60 Hz

≥ 5,5 kW: ∆ 400 V, 50 Hz and ∆ 460 V, 60 Hz - Protection class: IP55

- Direction of rotation: Clockwise

- Screw spindle and drive spindle: High performance steel, specially hardened

- Screw housing: Cast iron with lamellar graphite EN-GJL-250 surface-treated

- Pressure housing: Cast iron with lamellar graphite EN-GJL-250

- Intake housing: Cast iron with lamellar graphite EN-GJL-250

- Rotary shaft lip-type seal: PTFE

- Mechanical seal: Hard meta / FKM (FPM)

- O-ring seal: FKM (FPM)

- Rolling bearing: With permanent lubrication

- Pump support: Aluminium

- Intake tube: Steel

- Positive displacement pump

- 3 spindles

- Pressure connection above reservoir plate

- Integrated pressure restriction valve

- Variable immersion depth due to intake tube

- Standardized motors, also available with frequency converter

- Seals: Mechanical seal for installation inside and outside the reservoir

- Longer spindles

- Axial counterbalancing thrust

Available downloads:

LMP screw pumps for delivery pressures up to 120 bar

Primary areas of use

- Machine tools

- Machining centers

- Central and decentralized coolant and preparation systems

- Booster stations

- Lubricant and hydraulic units

- Among other things

Due to its wear-resistant design, the LMP series is especially suitable for:

- Demanding applications involved in processing difficult to mill materials such as aluminium and stainless steel

- Various precision applications such as in the aerospace industry

- Grinding applications

LMP screw pumps with frequency converters

An LMP pump with integrated frequency converter enables optimum usage depending on the application. It adjusts the electrical output to the application's requirements and thus saves energy. Adjustment can be made to various operating points in the characteristics field to configure the pump ideally for the area of application. This adjustment can be made either smoothly or with defined increments as required. If needed, a single pump with a frequency converter can be used to accomplish the tasks of several pumps (without speed adjustment). Full separation of the motor from the pump allows integration of the speed adjustable operation for retrofitters as well.

Advantages

- Huge output range

- Optimum adjustment to the respective machining process

- Universal adjustability of the pump speed through all pressure ranges

- Frequency converters work almost no loss and are entirely maintenance-free

- Regardless of voltage fluctuation in the power supply

- Speed adjustment ensures effective delivery rate and usage

- Economically convincing, energy efficient alternative to standard solutions

- High dependability

- Long service life

- Quick and simple commissioning

- Convenient integration in machine control

- Compact design

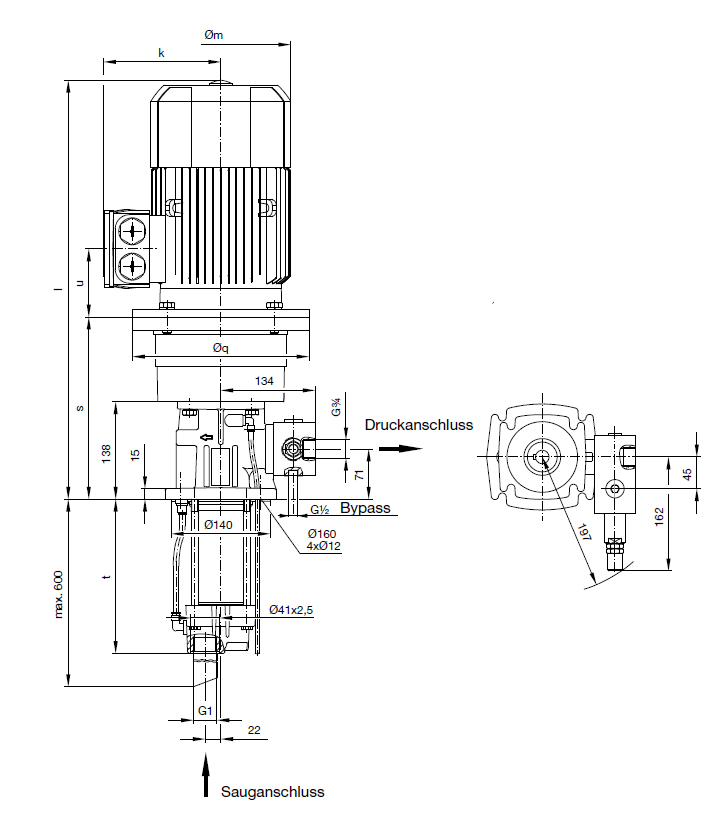

LMP 10, 11, 20, 21, 22, 12, 13 dimensions

Viewed