2/2-Way Valves

2/2-Way Valves 161-110-018+924

4/2-way Solenoid Valve 161-140-050

4/2-way Solenoid Valve 161-140-050 161-140-050+924

Accessories for KFA pumps

Accessories for KFA pumps KFA1.01

Accessories for KFAS pumps

Accessories for KFAS pumps KFAS1.08

Anschlussstücke, kegelig

Anschlussstücke, kegelig 402-003K

Banjo Connector cross form

Banjo Connector cross form 504-110

Banjo Connector L-form

Banjo Connector L-form 504-114

Block Metering Device PBA

Block Metering Device PBA PBA-Verteiler

Block Metering Device VPBG

Block Metering Device VPBG VPBG-3

Block Metering Device VPBM

Block Metering Device VPBM VPBM-3

Cap / Cover for Single-line Pumps

Cap / Cover for Single-line Pumps 898-660-056

Check Valves / Ball Valves

Check Valves / Ball Valves VPG-RV

Compact Greaser ETP

Compact Greaser ETP ETP2WZ-CXCXX-B+924

Compact Pump MCP, manual

Compact Pump MCP, manual MCP15-10A01X2-F05

Conical Lubrication Nipple with valve

Conical Lubrication Nipple with valve 996-001-890

Connection Cable for KFAS / KFGS / KFG

Connection Cable for KFAS / KFGS / KFG 997-000-760

Connector for Metering Devices

Connector for Metering Devices VKR2.U2

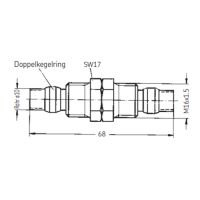

Connector for Ø 10 mm and Ø 12 mm, cylindrical

Connector for Ø 10 mm and Ø 12 mm, cylindrical 410-160

Connector for Ø 2,5 mm, cylindrical

Connector for Ø 2,5 mm, cylindrical 843-130-024

Connector for Ø 4 mm, cylindrical

Connector for Ø 4 mm, cylindrical 404-004

Connector for Ø 6 mm, cylindrical

Connector for Ø 6 mm, cylindrical 406-158

Connector for Ø 8 mm, cylindrical

Connector for Ø 8 mm, cylindrical 408-004

Connector, Whithworth Threads

Connector, Whithworth Threads 404-403W

Connectors for VPBM

Connectors for VPBM VPBM-C2

Products from SKF

SKF – Market Leader in Lubrication Management

SKF, a global leader in bearing and lubrication technology, provides innovative solutions for industrial applications across various sectors. Since its founding in 1907, SKF has specialized in the development, manufacturing, and optimization of rolling bearings, seals, mechatronics, services, and lubrication solutions. With a strong focus on quality and innovation, SKF helps companies reduce operating costs, increase efficiency, and extend the lifespan of their machinery.

Bearing Solutions and Product Portfolio

SKF is renowned for its high-quality rolling bearings used in a wide range of applications. From small precision bearings for instruments to large bearings for heavy machinery, SKF offers tailored solutions for every requirement. The product range includes:

- Deep Groove Ball Bearings: Ideal for high speeds and low friction.

- Self-Aligning Ball Bearings: Perfect for applications with misalignment issues.

- Cylindrical Roller Bearings: Optimized for heavy loads and harsh operating conditions.

- Tapered Roller Bearings: Designed for combined axial and radial loads.

In addition to bearings, SKF offers seals, linear technology, sensors, and lubrication systems that optimize machine operation and extend their lifespan.

Innovative Lubrication Management at SKF

SKF's lubrication management is a vital component of modern industrial applications. It ensures efficient machine operation, maximizes component life, and minimizes operating costs. SKF provides a wide range of central lubrication systems that can seamlessly integrate into existing facilities.

Systems like MINILUB or WINDLUB are known for their precision and sustainability. They are ideal for demanding applications such as wind turbines, the printing industry, or paper manufacturing. SKF takes a holistic approach, from design to integration and maintenance. A standout feature is Minimum Quantity Lubrication (MQL), which not only saves resources but also enhances productivity and surface quality in metalworking.

The Acquisition of Willy Vogel AG by SKF – A Milestone

In 2004, SKF acquired Willy Vogel AG, significantly expanding its portfolio in central lubrication. Willy Vogel AG, a renowned provider of lubrication solutions, was known for its expertise in developing systems for machine tools, printing presses, and other industries. This acquisition allowed SKF to diversify its lubrication solutions, gain access to advanced technology, and broaden its customer base.

A key highlight of this integration is the addition of central lubrication systems such as the LubriLean and VARIOLUB systems. These systems deliver lubrication efficiently and precisely where needed and offer high flexibility due to their modular design, meeting specific requirements.

Automatic Lubrication Systems by SKF

SKF's automatic lubrication systems ensure precise and continuous lubrication, enhancing efficiency and reducing human errors in manual lubrication. Key benefits include:

- Precision: The right amount of lubricant at the right time.

- Maintenance-Free: Reduction of manual intervention.

- Cost Reduction: Lower lubricant consumption and wear costs.

SKF offers various systems, such as single-line, progressive, or multi-line systems, tailored to your machines' requirements.

Centralized Lubrication Systems for Complex Applications

SKF's centralized lubrication systems are particularly suited for large or hard-to-reach machine areas. These systems simultaneously lubricate multiple points, saving time and increasing efficiency. Typical applications include conveyor systems, construction machinery, and production lines.

Features of SKF Centralized Lubrication Systems:

- Flexibility: Integration into existing machine concepts.

- Reliability: Consistent lubrication even under challenging conditions.

- Adaptability: Suitable for both oil and grease lubrication.

SKF Lubrication Distributors

Distributors are essential components of any centralized lubrication system. They regulate and control the amount of lubricant delivered to individual points. Depending on the application, various types of distributors are used:

- Progressive Distributors: Deliver fixed amounts of lubricant sequentially to different points, ideal for applications requiring precise and continuous lubrication, such as production plants or filling stations.

- Two-Line Distributors: Designed for large systems with many lubrication points, offering flexibility and robustness, even in harsh environments like heavy industry.

- Single-Line Distributors: A cost-effective solution for smaller machines or systems with moderate requirements.

The availability of distributors in different designs and materials allows precise adaptation to specific system requirements.

Lubrication Technology Fittings and Components by SKF

High-quality fittings and components are crucial for the safe operation and longevity of centralized lubrication systems. These include:

- Fittings and Lines: Securely transport lubricant to distributors and lubrication points, available in various designs like push-in and cutting-ring fittings.

- Filters and Level Sensors: Ensure the cleanliness and availability of lubricant.

- Pump Elements and Control Units: Enable precise dosing and distribution.

These components come in different sizes and materials, ensuring compatibility with specific machine requirements while providing reliability and ease of maintenance.

Spare Parts – Sustainability and Durability

SKF emphasizes the availability of spare parts to ensure the long-term operational safety of systems. From replacing defective pump elements to new hoses or seals, SKF offers a comprehensive range to prevent costly downtimes and maintain efficiency.

The modular design of many SKF products allows for easy replacement or expansion of individual components, contributing to resource conservation and sustainability by avoiding complete system replacements.

High-Quality Lubricants – Perfectly Tailored to Your Needs

In addition to lubrication systems, SKF provides a wide selection of lubricants specifically designed for various operating conditions. Whether extreme temperatures, heavy loads, or hygienic requirements, SKF lubricants ensure maximum performance.

Popular product groups include:

- SKF LGWA 2: An all-purpose grease for a wide range of applications.

- SKF LGHP 2: A high-performance high-temperature grease for demanding applications.

- SKF LGFP 2: Food-grade grease for hygienically sensitive areas.

Digital Monitoring for Maximum Efficiency

A highlight in SKF's portfolio is the integration of sensors and monitoring technologies into lubrication systems. With tools like SKF Enlight Collect and SKF Lubrication Planner, lubrication processes can be monitored and optimized in real-time. Benefits of this digitalization include:

- Early Problem Detection: Prevent failures through predictive maintenance.

- Optimized Maintenance Intervals: More efficient use of personnel and resources.

- Data-Driven Decisions: Maximize system performance based on accurate data.

Why Choose SKF Lubrication Technology?

SKF combines over 100 years of experience in bearing and lubrication technology with cutting-edge advancements in automation and digitalization. Its lubrication and lubrication management solutions are designed to reduce operating costs, increase machine availability, and minimize wear.

Partnering with SKF provides companies with customized advice, high-performance products, and an extensive service network. From small machines to complex production systems, SKF's lubrication technology solutions offer a competitive advantage.

Digitalization and Sustainability

SKF continuously invests in digital technologies and sustainable processes to meet the growing demands of Industry 4.0. With digital solutions like SKF Enlight or SKF Rotating Equipment Performance (REP), the company enables predictive maintenance and improves overall system performance.

Sustainability is also a focus for SKF. Energy-efficient products and eco-friendly manufacturing processes help customers reduce CO₂ emissions and use resources more efficiently.

Expertise Across Industries

SKF products and solutions are applied in a variety of industries, including:

- Automotive Industry: High-precision bearings and lubrication solutions for e-mobility and traditional drivetrains.

- Energy Sector: Solutions for wind turbines, solar technology, and other renewable energy sources.

- Heavy Industry: Durable bearings and lubrication systems for mining, steel production, and cement plants.

- Food Industry: Hygienic bearings and lubricants meeting the industry's stringent requirements.

Why Choose SKF Lubrication for Your Business?

SKF stands for quality, reliability, and technological excellence from Sweden. With a global network of production and service locations, SKF provides swift and effective support. The combination of comprehensive expertise, innovative products, and strong service offerings makes SKF an essential partner for companies looking to optimize machine performance, avoid downtimes, and enhance productivity.

Benefit from SKF’s high-quality centralized lubrication products and solutions through its certified distributor Vogel Schmiertechnik – the key to smooth and efficient operations.